Expert Machining Services Solutions

Unlock high-quality, tailored machining services for all your manufacturing needs. Expert CNC solutions for precision parts delivered on time.

What does CNC machining do

CNC machining is an automated manufacturing process that uses computer numerical control (CNC) technology to create precise parts from various materials. It encompasses operations like milling, turning, drilling, and grinding, enabling high accuracy and repeatability. CNC machining is versatile, working with metals, plastics, and composites, making it ideal for custom components and intricate designs. It integrates with CAD/CAM software for efficient design and production, resulting in reduced waste and increased efficiency in industries like aerospace, automotive, and medical.

CNC Machining Services Classification

CNC machining is a highly versatile manufacturing process that involves the use of automated control via computer software to precisely manage the movement of machine tools. CNC machining can be classified into different categories based on several factors, such as the type of machines used, the machining process, application, axis configuration, and material type. Understanding these classifications is essential to optimize the use of CNC machining for different industrial applications.

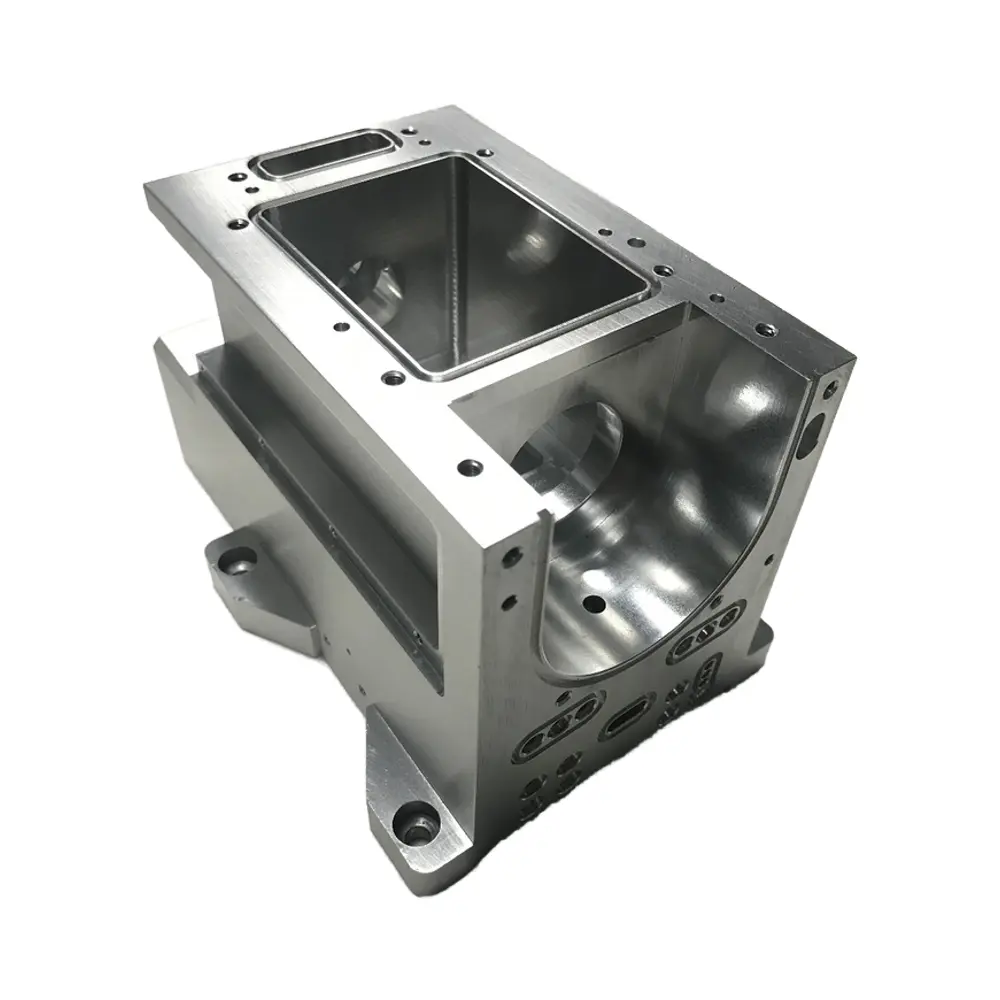

CNC Machining

Offering high-quality precision CNC machining services for custom parts. Our advanced CNC machines ensure accuracy, durability, and fast turnaround. Perfect for industries needing reliable, custom machining solutions. Contact us for competitive pricing!

CNC Milling

As leading CNC milling machine manufacturers, we specialize in delivering high-precision milling solutions for various industries. Our state-of-the-art machines ensure exceptional quality and efficiency. Contact us to explore custom options that enhance your production capabilities and meet your specific requirements!

CNC Turning

As a premier CNC turning parts manufacturer, we specialize in creating high-quality, custom-turned components for various applications. Our advanced CNC turning technology ensures precision and efficiency, meeting your exact specifications. Partner with us for reliable solutions that elevate your manufacturing process!

5 Axis CNC Machining

Our 5 axis CNC machining services offer unparalleled precision and versatility for complex geometries. With advanced technology and skilled technicians, we deliver high-quality components tailored to your specifications. Optimize your production process and enhance efficiency with our expert 5 axis machining solutions!

Precision Machining

Specializing in CNC precision manufacturing, we deliver high-quality, custom-engineered components with exceptional accuracy. Our advanced machinery and skilled team ensure reliable results for various industries. Choose us for precision machining solutions that enhance your production efficiency and meet your unique needs!

Manufacturing Process of Machining Services

1. Initial Consultation and Design Review:The process begins with understanding the customer’s specific requirements. This includes detailed discussions on part design, material selection, tolerances, and the intended application of the component.

2. Material Procurement and Preparation:Based on the customer’s design and specifications, the appropriate raw materials (metals, plastics, composites) are sourced and prepared. The material is then cut into the required size and shape for machining.

3. CAD/CAM Programming:The customer’s design is converted into a 3D CAD model, followed by generating CNC machine instructions through CAM software. This ensures precise control over the machining process, guiding the tools to shape the material accurately.

4. Machine Setup and Tool Selection:Once the CAM program is ready, the necessary tools (such as drills, lathes, or mills) are selected and installed in the CNC machine. The machine is calibrated, and the raw material is securely clamped in place to prevent movement during operations.

5. Precision Machining Operations:The CNC machine begins executing the programmed instructions, performing operations like milling, turning, drilling, or grinding. These processes remove material layer by layer to create the desired part shape and features.

6. Real-time Monitoring and Adjustment:During the machining process, operators or automated systems monitor tool performance and material quality to ensure accuracy. Adjustments may be made to maintain precision and avoid any defects in the part.

7. Secondary Operations (If Required):Additional processes such as threading, engraving, or slotting may be performed to complete the part. These secondary operations ensure that complex or intricate features are machined as needed.

8. Finishing and Surface Treatment:Depending on the part’s requirements, finishing operations like polishing, anodizing, or coating are applied. These treatments enhance the surface quality, durability, and aesthetic appeal of the final product.

9. Quality Inspection and Testing:After machining and finishing, the parts undergo rigorous quality checks, including dimensional verification, surface finish inspection, and functional testing. This ensures that all parts meet customer specifications and industry standards.

10. Packaging and Shipping:Once the parts pass inspection, they are carefully cleaned, packaged, and prepared for shipment. For some customers, additional assembly or post-production services may be provided before final delivery.

Features that Make Our Machining Services Unique

Our Certificates

Machining Services FAQs

We work with a wide variety of materials, including metals (aluminum, steel, brass), plastics, and composites. We can source the material based on your requirements.

We utilize advanced CNC machines for precision and conduct rigorous quality inspections, including dimensional checks and surface finish testing, to ensure every part meets specifications.

Lead times depend on the complexity and quantity of the order, but we typically deliver within 2-4 weeks. Expedited services are also available upon request.

Yes, we accommodate both small prototype runs and large-volume production orders, scaling our services to meet your needs efficiently.

Yes, we provide secondary services such as surface treatments (polishing, anodizing) and assembly to ensure your parts are production-ready when delivered.

We take customer confidentiality seriously, ensuring that your designs and data are protected through strict privacy policies and secure processes during manufacturing.

Blogs About Machining Services

Cast Aluminum vs. Machined Aluminum: Choosing the Right Material for Your Project

In the world of manufacturing, selecting the right aluminum product is crucial for optimizing performance, cost, and durability. This article explores the key differences between cast aluminum and machined aluminum, helping industries from aerospace to consumer products make informed decisions. Understanding these materials’ properties and applications can ensure that your next project achieves the highest quality standards.

Ensuring Precision in CNC Milling for High-Quality Machined Parts

In today’s competitive manufacturing world, achieving the highest level of precision in CNC milling is essential for creating reliable and efficient machined parts. This guide explores how to ensure precision in your project by leveraging advanced CNC milling machines and strategies. For industries such as aerospace, automotive, and medical devices, mastering precision is a crucial factor for success.

Mastering the Countersink: Drilling Perfect Holes in Metal Workpieces

Achieving a flawless countersink is essential for ensuring screw heads sit flush with or below the surface of a metal workpiece. This guide will explore the intricacies of creating a countersink hole and provide you with the insights needed to master this technique. Whether you’re in aerospace, construction, or crafting precision metal parts, understanding how to countersink a screw properly is crucial for seamless assembly and optimal durability.