Precision CNC Manufacturing Excellence

Unlock top-tier CNC precision manufacturing with cutting-edge solutions designed for accuracy, quality, and reliability. Elevate your projects with unmatched CNC machining precision.

Your Reliable Precision Machining Manufacturer

With over 10 years of expertise, we are a trusted leader in precision machining, offering advanced CNC solutions tailored to meet industry demands. Our dedication to quality and innovation is driven by a team of seasoned professionals who leverage the latest technology to deliver high-precision, reliable results. We specialize in producing custom components with unparalleled accuracy, ensuring each part meets the highest standards of durability and functionality. From complex designs to tight tolerances, we are committed to excellence, providing high-quality CNC precision manufacturing that powers industries worldwide. Choose us for experience, precision, and a commitment to quality that sets us apart.

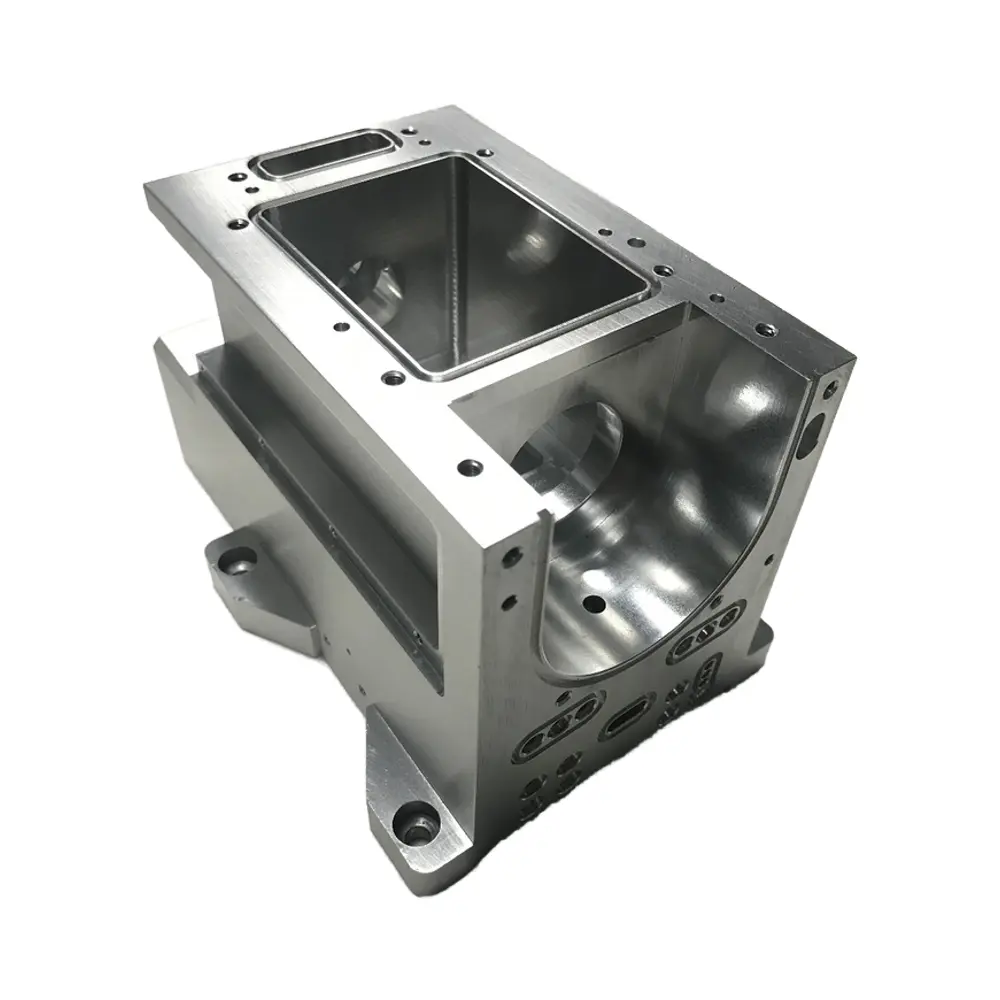

Precision Machining Customer Cases

Discover our Precision Machining customer cases showcasing high-quality CNC solutions tailored to meet diverse industry needs. With 10 years of experience, our case studies highlight our expertise in delivering precise, reliable machining services that drive success for our clients.

Manufacturing Process of Precision Machining

1. Consultation and Design Analysis:Our process begins with a thorough consultation to understand your specific needs. We analyze your design to ensure it aligns with precision machining capabilities, discussing material selection, tolerances, and production methods.

2. CNC Programming:Once the design is finalized, our skilled engineers create precise CNC programs tailored for your project. Using advanced software, we simulate machining operations to optimize efficiency and accuracy.

3. Material Preparation:We source high-quality materials suitable for your application. Our team prepares and inspects raw materials, ensuring they meet the required specifications before moving to the machining stage.

4. CNC Machining:Utilizing state-of-the-art CNC machines, we execute the machining process. Our advanced technology ensures precision and consistency, enabling us to produce intricate components with tight tolerances.

5. Quality Control:Rigorous quality control measures are implemented throughout the manufacturing process. Our team conducts in-process inspections and final checks using precision measurement tools to ensure each part meets stringent quality standards.

6. Finishing and Surface Treatment:We offer a range of finishing options, including polishing, coating, and anodizing, to enhance the durability and aesthetics of your components. This step is crucial for achieving the desired performance and appearance.

7. Packaging and Delivery:Once the components pass quality inspection, we carefully package them to prevent damage during transit. Our logistics team ensures timely delivery to meet your production schedules.

8. After-Sales Support:Our commitment doesn’t end with delivery. We provide ongoing support and consultation, ensuring your satisfaction with our precision machining services and addressing any concerns that may arise.

Features that Make Our Precision Machining Unique

Our Certificates

Precision Machining FAQs

Precision machining is a manufacturing process that utilizes advanced CNC machines to create components with extremely tight tolerances and high levels of accuracy. This process is essential for producing intricate parts used in various industries, ensuring they meet specific design requirements.

Precision machining can accommodate a wide range of materials, including metals (such as aluminum, steel, and titanium), plastics, and composites. Our expertise allows us to select the most suitable material for your application, ensuring optimal performance and durability.

The tolerances achievable in precision machining can vary based on the complexity of the part and the capabilities of the equipment used. Generally, we can achieve tolerances as tight as ±0.001 inches (±0.025 mm) or better, depending on the specifications of your project.

The timeline for precision machining depends on various factors, including the complexity of the part, material selection, and production volume. After the initial consultation and design analysis, we can provide an estimated lead time to meet your project deadlines.

Yes, we specialize in custom precision machining. Our team works closely with you to understand your unique design requirements, allowing us to create tailored solutions that meet your specifications. Whether it’s a one-off prototype or a large production run, we are equipped to handle your needs.

We implement a rigorous quality assurance process throughout the machining cycle. This includes in-process inspections, final measurements using precision tools, and adherence to industry standards. Our commitment to quality ensures that every part we produce meets your exact specifications and performs reliably in its intended application.

Blogs About Precision Machining

Cast Aluminum vs. Machined Aluminum: Choosing the Right Material for Your Project

In the world of manufacturing, selecting the right aluminum product is crucial for optimizing performance, cost, and durability. This article explores the key differences between cast aluminum and machined aluminum, helping industries from aerospace to consumer products make informed decisions. Understanding these materials’ properties and applications can ensure that your next project achieves the highest quality standards.

Ensuring Precision in CNC Milling for High-Quality Machined Parts

In today’s competitive manufacturing world, achieving the highest level of precision in CNC milling is essential for creating reliable and efficient machined parts. This guide explores how to ensure precision in your project by leveraging advanced CNC milling machines and strategies. For industries such as aerospace, automotive, and medical devices, mastering precision is a crucial factor for success.

Mastering the Countersink: Drilling Perfect Holes in Metal Workpieces

Achieving a flawless countersink is essential for ensuring screw heads sit flush with or below the surface of a metal workpiece. This guide will explore the intricacies of creating a countersink hole and provide you with the insights needed to master this technique. Whether you’re in aerospace, construction, or crafting precision metal parts, understanding how to countersink a screw properly is crucial for seamless assembly and optimal durability.