Precision CNC Solutions for You

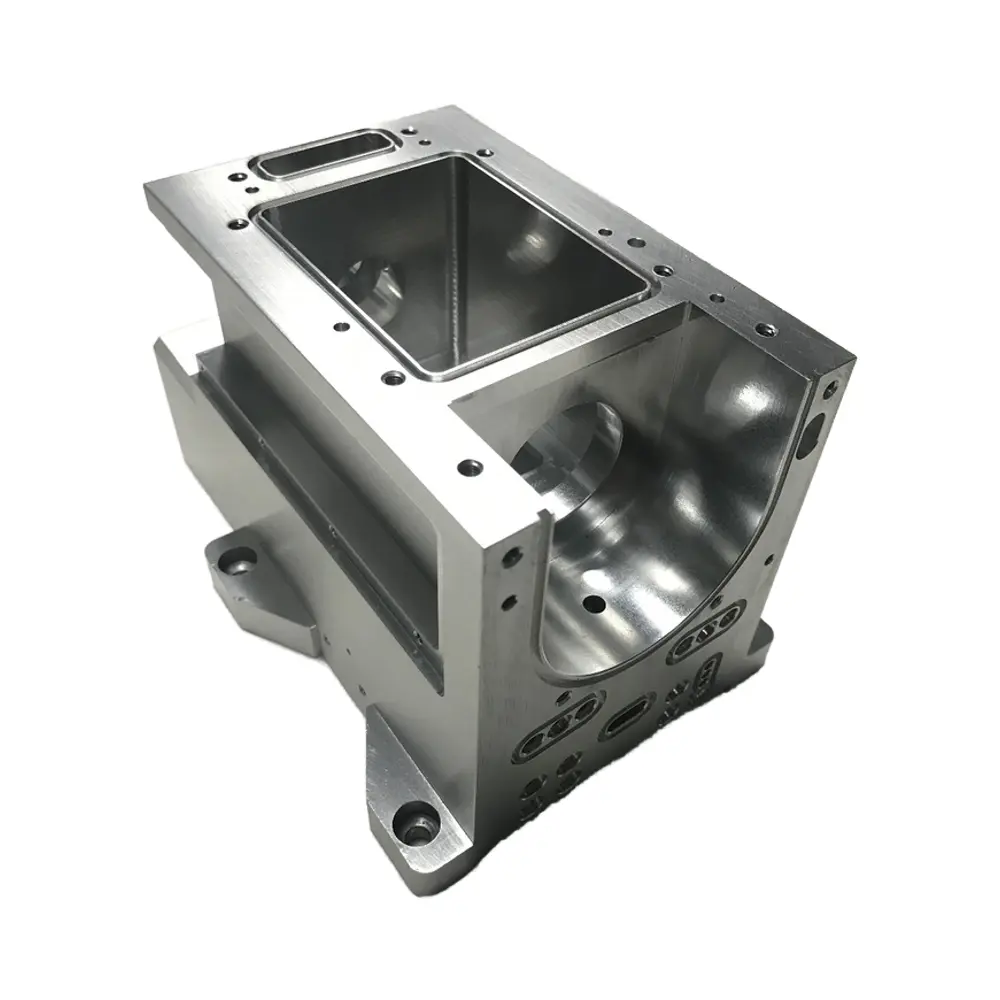

Unlock the potential of your projects with our tailored CNC solutions. Experience exceptional accuracy, efficiency, and quality, ensuring your manufacturing needs are met with precision. Partner with us for innovative CNC technology and expert support.

What is a CNC solution?

A CNC solution refers to the use of Computer Numerical Control technology to automate and optimize manufacturing processes. It enables precise and efficient fabrication of parts through computer-controlled machines, ensuring high accuracy and repeatability.

CNC solutions are versatile, allowing for various applications such as milling, turning, and laser cutting, while also offering customization for complex designs. This technology enhances production efficiency, reduces waste, and meets unique customer specifications in diverse industries.

CNC Solutions Classification

CNC solutions encompass a variety of technologies and processes used in automated manufacturing. These solutions can be classified based on machinery type, application, technology, industry, and automation level. Understanding these classifications helps businesses choose the right CNC solutions tailored to their specific needs, enhancing efficiency, precision, and customization in production.

Rapid Prototyping

Our CNC rapid prototyping services in China offer fast and accurate production of prototypes for various industries. Utilizing advanced CNC technology, we deliver high-quality parts with quick turnaround times, allowing you to test designs and iterate efficiently. Trust us for reliable, cost-effective prototyping solutions.

On Demand Manufacturing

Our on-demand CNC services provide flexible manufacturing solutions tailored to your specific needs. With rapid turnaround times and precision machining, we deliver high-quality parts exactly when you need them. Whether for prototypes or small batches, trust us for efficient and cost-effective on-demand manufacturing.

Surface Finishing

Experience the best precision CNC machining manufacturing with our surface finishing services. We offer custom material options tailored to your specific requirements, ensuring optimal quality and durability. Enhance your parts' appearance and performance with our expert finishing techniques, delivering exceptional results every time.

Assembly

Our CNC assembly service specializes in assembling high-quality components using various materials tailored to your specifications. With precision and expertise, we ensure seamless integration of parts, enhancing the functionality and durability of your products. Trust us for efficient, reliable, and cost-effective assembly solutions.

Manufacturing Process of CNC Solutions

1. Consultation and Design:Collaborate with clients to understand project specifications and requirements.Utilize CAD software to create detailed designs and prototypes, ensuring alignment with client expectations.

2. Material Selection:Identify and source suitable materials based on project needs, considering factors like strength, weight, and cost.Provide options for custom materials to enhance product performance.

3. Machining Setup:Prepare CNC machines for production, including tool selection, calibration, and programming.

Ensure all equipment is properly maintained for optimal performance.

4. CNC Machining:Execute machining processes, including milling, turning, drilling, or laser cutting, to create precise components.Monitor the machining process to ensure adherence to specifications and quality standards.

5. Quality Control:Conduct thorough inspections during and after the machining process using advanced measuring tools.

Implement quality assurance protocols to detect and address any defects or deviations from specifications.

6. Surface Finishing:Apply finishing techniques such as sanding, polishing, or coating to enhance the aesthetic and functional properties of the components.

Ensure that finished parts meet the desired surface quality and durability standards.

7. Assembly:Assemble components with precision, ensuring proper fit and functionality.Use automated and manual techniques to guarantee high-quality assembly results.

8. Packaging and Shipping: Package finished products securely to prevent damage during transportation.

Coordinate logistics to ensure timely delivery to clients, meeting agreed-upon timelines.

9. Post-Production Support: Offer ongoing support and assistance for any client inquiries or modifications needed after delivery.Gather feedback to continuously improve manufacturing processes and customer satisfaction.

Features that Make Our CNC Solutions Unique

Our Certificates

CNC Solutions FAQs

We offer a wide range of CNC solutions, including CNC machining, milling, turning, laser cutting, and assembly services. Our capabilities are tailored to meet diverse manufacturing needs across various industries.

We implement rigorous quality control measures throughout the manufacturing process. This includes thorough inspections, precision measurements, and adherence to industry standards, ensuring that every product meets our high-quality benchmarks.

Yes, we specialize in custom CNC solutions tailored to your specific requirements. Our team collaborates with you to develop designs and specifications that align with your unique needs, ensuring that the final product meets your expectations.

We work with a wide variety of materials, including metals (like aluminum and stainless steel), plastics, and composites. Our team can advise on the best material options based on your project requirements and desired outcomes.

Lead times vary depending on project complexity and size. We strive for efficient production and can provide a specific timeline once we understand your project scope. Generally, we aim to deliver projects promptly without compromising quality.

Absolutely! We offer post-production support to address any questions or modifications you may need after receiving your products. We value customer feedback and are committed to ensuring your satisfaction with our CNC solutions.

Blogs About CNC Solutions

Cast Aluminum vs. Machined Aluminum: Choosing the Right Material for Your Project

In the world of manufacturing, selecting the right aluminum product is crucial for optimizing performance, cost, and durability. This article explores the key differences between cast aluminum and machined aluminum, helping industries from aerospace to consumer products make informed decisions. Understanding these materials’ properties and applications can ensure that your next project achieves the highest quality standards.

Ensuring Precision in CNC Milling for High-Quality Machined Parts

In today’s competitive manufacturing world, achieving the highest level of precision in CNC milling is essential for creating reliable and efficient machined parts. This guide explores how to ensure precision in your project by leveraging advanced CNC milling machines and strategies. For industries such as aerospace, automotive, and medical devices, mastering precision is a crucial factor for success.

Mastering the Countersink: Drilling Perfect Holes in Metal Workpieces

Achieving a flawless countersink is essential for ensuring screw heads sit flush with or below the surface of a metal workpiece. This guide will explore the intricacies of creating a countersink hole and provide you with the insights needed to master this technique. Whether you’re in aerospace, construction, or crafting precision metal parts, understanding how to countersink a screw properly is crucial for seamless assembly and optimal durability.