Precision CNC Sheet Metal Fabrication

Transform your ideas into reality with our expert CNC sheet metal fabrication services. As leading manufacturers, we utilize advanced CNC machines for unmatched quality and precision. Partner with us for innovative solutions tailored to your needs!

Your Reliable Sheet Metal Fabrication Manufacturer

With over 10 years of experience in the industry, we are a premier provider of sheet metal fabrication solutions. Our commitment to excellence is underscored by our use of leading technology and advanced CNC machines, enabling us to deliver high-quality products tailored to meet the unique needs of our clients.

Our professional team of skilled engineers and technicians is dedicated to precision and innovation, ensuring that every project meets the highest standards. We pride ourselves on fostering strong partnerships with our customers, providing not only exceptional fabrication services but also expert guidance throughout the process.

Whether you require custom components or large-scale production, we are here to turn your vision into reality with efficiency and reliability. Partner with us for your sheet metal fabrication needs and experience the difference that expertise and quality can make.

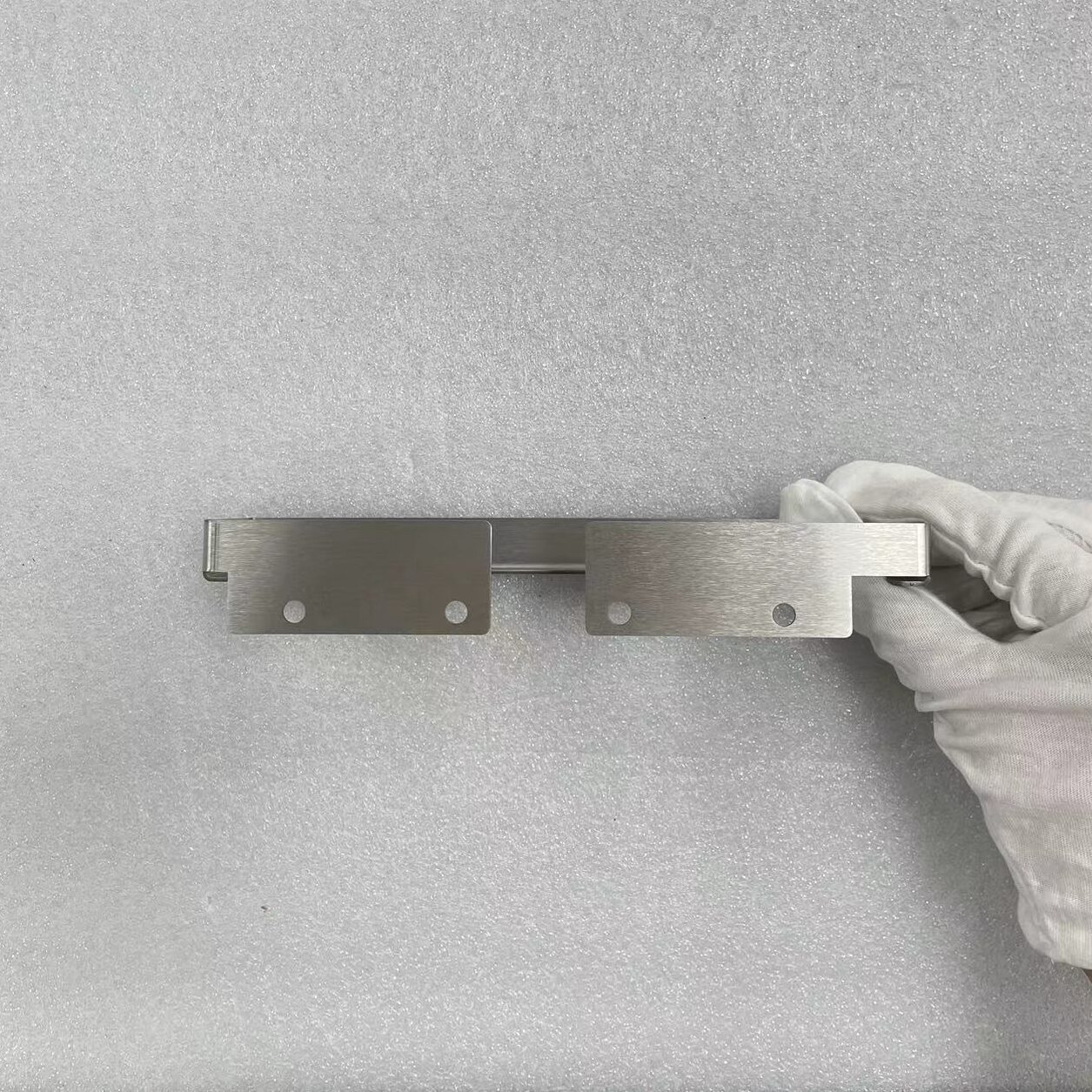

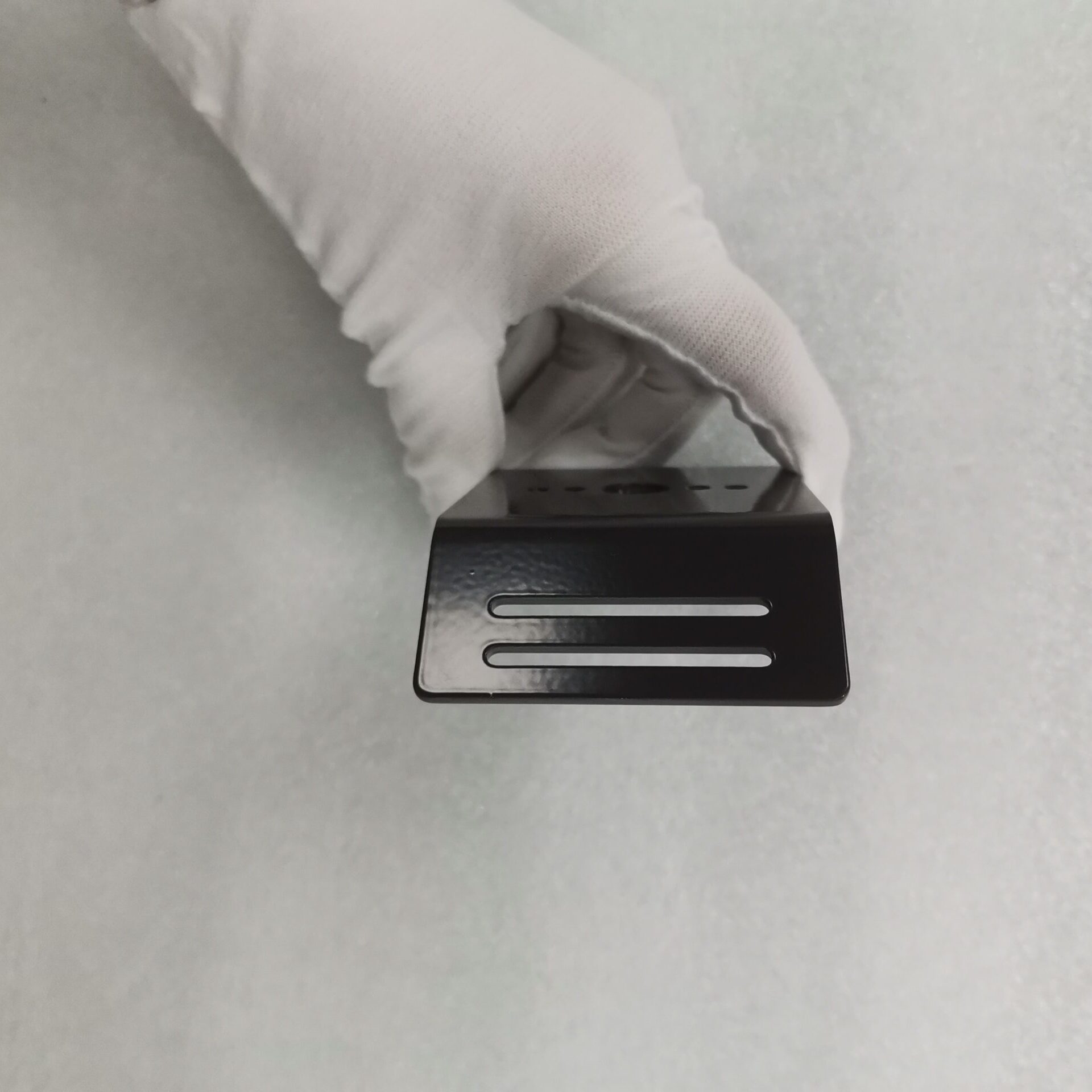

Sheet Metal Fabrication Customer Cases

Explore our diverse range of successful sheet metal fabrication customer cases. From custom designs to high-volume production, discover how our advanced CNC technology and skilled team have delivered high-quality solutions tailored to various industries. Each case showcases our commitment to precision and customer satisfaction, making us a trusted partner in sheet metal fabrication. Learn more about our innovative projects and how we can help bring your ideas to life.

Manufacturing Process of Sheet Metal Fabrication

1. Design and Prototyping:We start with a comprehensive design phase, utilizing advanced CAD software to create precise blueprints. Prototyping allows us to validate designs and make necessary adjustments before production.

2. Material Selection:We offer a wide range of high-quality materials, including steel, aluminum, and stainless steel. Our team helps you choose the best material based on your project requirements and specifications.

3. Cutting:Our state-of-the-art CNC cutting machines ensure accurate and efficient cutting of sheet metal. Techniques such as laser cutting, plasma cutting, and water jet cutting are employed to achieve clean edges and intricate shapes.

4. Forming:Using advanced CNC bending and forming equipment, we shape the metal into the desired angles and contours. This process ensures consistent results and high precision for complex geometries.

5. Welding and Assembly:Our skilled welders utilize various welding techniques, including MIG and TIG welding, to assemble components securely. This step ensures the structural integrity of the final product.

6. Finishing:We offer a range of finishing options, such as powder coating, anodizing, and painting, to enhance durability and aesthetics. Our finishing processes are designed to meet specific industry standards and customer preferences.

7. Quality Control:Rigorous quality checks are conducted throughout the manufacturing process to ensure that every component meets our high standards. We employ precision measuring tools and techniques to guarantee accuracy and reliability.

8. Packaging and Delivery:Once completed, our products are carefully packaged to prevent damage during transit. We ensure timely delivery, so you receive your products when you need them, ready for installation or use.

Features that Make Our Sheet Metal Fabrication Unique

Our Certificates

Sheet Metal Fabrication FAQs

We work with a variety of materials, including steel, aluminum, stainless steel, brass, and copper. Our team can help you choose the most suitable material based on your project’s specific requirements and desired properties.

Lead times can vary depending on the complexity of the project and our current workload. Generally, we aim to complete standard projects within 2-4 weeks. For urgent orders, we offer expedited services to meet tight deadlines.

Can you handle custom designs and prototypes?

Yes, we specialize in custom sheet metal fabrication and can create prototypes to match your unique specifications. Our advanced CAD software allows us to develop precise designs tailored to your needs, ensuring optimal performance and fit.

We offer a wide range of finishing options, including powder coating, anodizing, painting, and plating. These finishes not only enhance the aesthetics of the final product but also provide added protection against corrosion and wear.

We implement comprehensive quality control measures throughout the fabrication process, including regular inspections and testing. Our skilled team utilizes precision measurement tools to guarantee that each component meets our high standards and your specifications.

Our minimum order quantity varies depending on the complexity of the design and the materials used. We accommodate both small and large-scale projects, so please contact us to discuss your specific needs and we will work with you to find a suitable solution.

Blogs About Sheet Metal Fabrication

Cast Aluminum vs. Machined Aluminum: Choosing the Right Material for Your Project

In the world of manufacturing, selecting the right aluminum product is crucial for optimizing performance, cost, and durability. This article explores the key differences between cast aluminum and machined aluminum, helping industries from aerospace to consumer products make informed decisions. Understanding these materials’ properties and applications can ensure that your next project achieves the highest quality standards.

Ensuring Precision in CNC Milling for High-Quality Machined Parts

In today’s competitive manufacturing world, achieving the highest level of precision in CNC milling is essential for creating reliable and efficient machined parts. This guide explores how to ensure precision in your project by leveraging advanced CNC milling machines and strategies. For industries such as aerospace, automotive, and medical devices, mastering precision is a crucial factor for success.

Mastering the Countersink: Drilling Perfect Holes in Metal Workpieces

Achieving a flawless countersink is essential for ensuring screw heads sit flush with or below the surface of a metal workpiece. This guide will explore the intricacies of creating a countersink hole and provide you with the insights needed to master this technique. Whether you’re in aerospace, construction, or crafting precision metal parts, understanding how to countersink a screw properly is crucial for seamless assembly and optimal durability.