Precision CNC Turning Parts Manufacturer

Unlock unmatched quality with our custom CNC turning parts. As a leading manufacturer, we specialize in delivering precision-engineered solutions tailored to your specifications. Elevate your projects with our expertise and commitment to excellence!

Your Reliable CNC Turning Manufacturer

Welcome to our company, your trusted partner in CNC turning solutions with over 10 years of industry experience. As a leading manufacturer, we leverage cutting-edge technology to deliver high-quality turning parts tailored to meet your unique needs. Our professional team of experts is dedicated to excellence, ensuring every product meets the highest standards of precision and durability. At our company, we are committed to providing innovative solutions and exceptional service, helping you elevate your projects and achieve your business goals. Discover the difference of partnering with a CNC turning leader today!

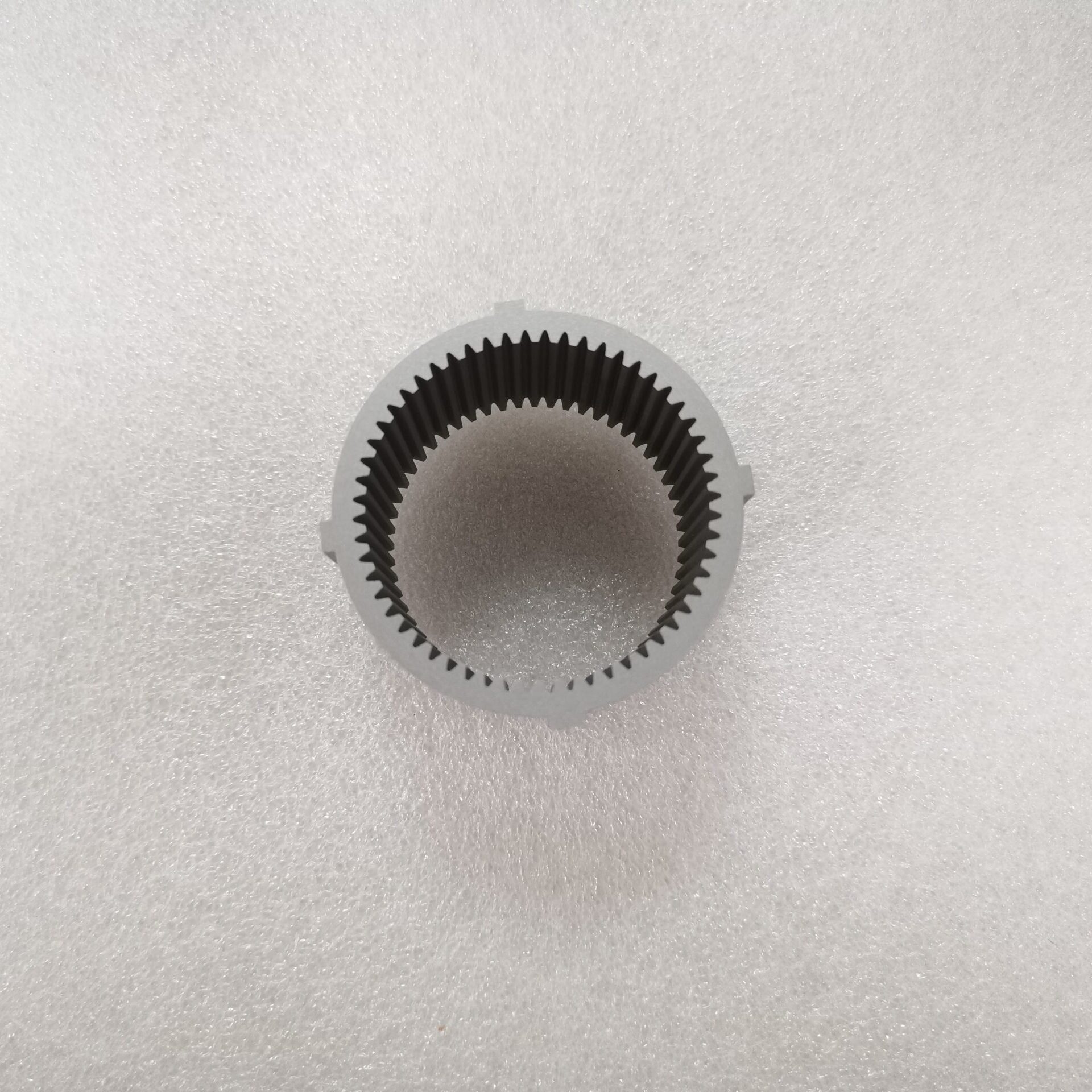

CNC Turning Customer Cases

Explore our diverse range of CNC turning customer cases showcasing successful projects across various industries. Discover how our precision-engineered turning parts have met the specific needs of our clients, enhancing their operations and driving success. Each case highlights our commitment to quality, innovation, and customer satisfaction. Partner with us for your next CNC turning project and experience the difference our expertise can make!

Manufacturing Process of CNC Turning

1. Material Selection: The process begins with selecting the appropriate material for the turning part, considering factors such as strength, durability, and application requirements.

2. Design and Prototyping: Using advanced CAD software, our team creates precise designs and prototypes, ensuring that every detail meets client specifications before moving to production.

3. Setup of CNC Lathe: The CNC lathe is configured according to the part design, including tooling and fixture setup, ensuring optimal performance and accuracy during machining.

4. Turning Operations: The CNC lathe executes turning operations, where the material is rotated against a stationary cutting tool. This removes material to create the desired shape, diameter, and finish.

5. Quality Control Checks: Throughout the manufacturing process, rigorous quality control checks are performed to ensure each part meets industry standards and client expectations.

6. Finishing Processes: After the turning operation, finishing processes such as polishing, anodizing, or coating are applied to enhance the part’s appearance and protect it from wear.

7. Final Inspection: Each finished product undergoes a final inspection, verifying dimensions, tolerances, and surface quality to ensure compliance with specifications.

8. Packaging and Delivery: Once approved, the parts are carefully packaged to prevent damage during transit and delivered to our clients on schedule.

This meticulous CNC turning manufacturing process guarantees high-quality, precision-engineered components that meet the demands of various industries.

Features that Make Our CNC Turning Unique

Our Certificates

CNC Turning FAQs

CNC turning can accommodate a wide range of materials, including metals (such as aluminum, steel, brass, and titanium), plastics, and composites. The choice of material depends on the specific application, desired properties, and manufacturing requirements.

Lead times for CNC turning projects can vary based on factors such as complexity, volume, and material availability. Generally, prototypes can be completed within a few days, while larger production runs may take several weeks. We provide clear timelines during the quoting process to help you plan accordingly.

Quality assurance is integral to our CNC turning process. We conduct rigorous inspections at various stages of production, including dimensional checks and surface quality assessments. Our skilled team utilizes advanced measuring equipment to ensure every part meets strict industry standards.

Absolutely! We specialize in custom CNC turning solutions. Whether you have a detailed CAD design or need assistance in creating a prototype, our team can work closely with you to bring your vision to life, ensuring the final product meets your specifications.

The cost of CNC turning is influenced by several factors, including material type, part complexity, quantity, and any additional finishing processes required. During the quoting process, we provide a detailed breakdown of costs to help you understand pricing and make informed decisions.

Our CNC turning services cater to a diverse range of industries, including aerospace, automotive, medical, electronics, and industrial manufacturing. We understand the unique requirements of each sector and tailor our solutions to meet their specific challenges and standards.

Blogs About CNC Turning

Cast Aluminum vs. Machined Aluminum: Choosing the Right Material for Your Project

In the world of manufacturing, selecting the right aluminum product is crucial for optimizing performance, cost, and durability. This article explores the key differences between cast aluminum and machined aluminum, helping industries from aerospace to consumer products make informed decisions. Understanding these materials’ properties and applications can ensure that your next project achieves the highest quality standards.

Ensuring Precision in CNC Milling for High-Quality Machined Parts

In today’s competitive manufacturing world, achieving the highest level of precision in CNC milling is essential for creating reliable and efficient machined parts. This guide explores how to ensure precision in your project by leveraging advanced CNC milling machines and strategies. For industries such as aerospace, automotive, and medical devices, mastering precision is a crucial factor for success.

Mastering the Countersink: Drilling Perfect Holes in Metal Workpieces

Achieving a flawless countersink is essential for ensuring screw heads sit flush with or below the surface of a metal workpiece. This guide will explore the intricacies of creating a countersink hole and provide you with the insights needed to master this technique. Whether you’re in aerospace, construction, or crafting precision metal parts, understanding how to countersink a screw properly is crucial for seamless assembly and optimal durability.