Precision 5 Axis CNC Machining

Unlock unparalleled precision with our 5 Axis CNC machining services. Ideal for complex parts, we deliver customized solutions that meet the highest industry standards.

Your Reliable 5 Axis CNC Machining Manufacturer

With a decade of expertise in 5 Axis CNC machining, our company stands at the forefront of precision manufacturing. We specialize in high-quality, intricate components, leveraging advanced technology and a skilled team dedicated to innovation and excellence. Our commitment to quality and customization has earned us a reputation as a trusted provider in the industry. Whether your project demands complex designs or high-tolerance parts, our solutions are tailored to meet the most rigorous standards, delivering reliability and performance that empower your success.

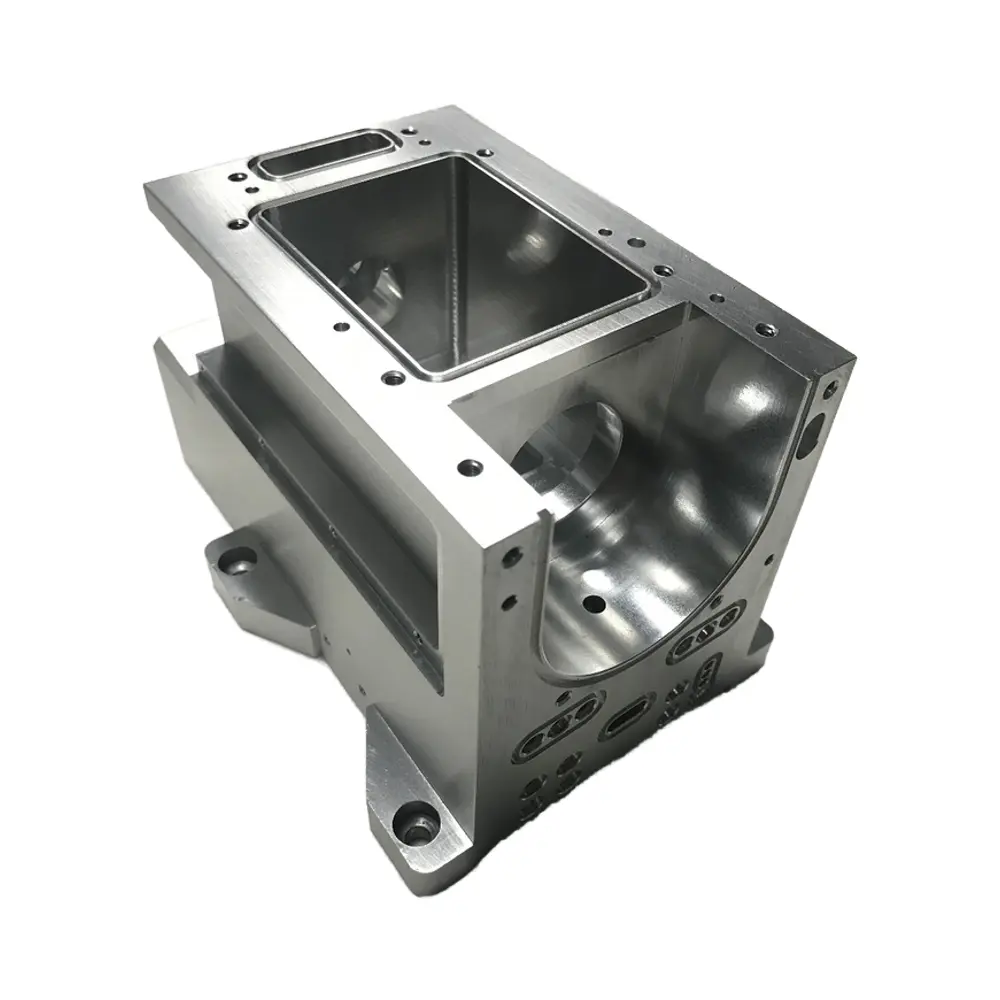

5 Axis CNC Machining Customer Cases

Explore real 5 Axis CNC machining customer cases showcasing our expertise in delivering high-precision, complex parts across various industries. Discover how our advanced 5 Axis CNC machining services meet diverse customer needs with quality and precision.

Manufacturing Process of 5 Axis CNC Machining

1. Design & Consultation:We collaborate with clients to understand project requirements, ensuring each design is optimized for 5 Axis CNC machining. Our team provides expert guidance to enhance precision and manufacturability.

2. CAD/CAM Programming:Using advanced CAD/CAM software, our engineers create detailed digital models, translating complex designs into precise machine instructions for seamless 5 Axis CNC production.

3. Material Selection:We assist in selecting the best materials for each project, ensuring compatibility and durability for high-performance results in line with industry standards.

4. Machine Setup & Calibration:Our skilled technicians set up and calibrate our 5 Axis CNC machines, adjusting each axis to ensure maximum accuracy and alignment with the specified design parameters.

5. Precision Machining:The machining process begins, utilizing synchronized movements across five axes. This advanced machining allows for the creation of complex, high-tolerance parts in fewer setups.

6. Quality Inspection:Post-machining, every component undergoes thorough inspection, using advanced measurement tools to verify adherence to specifications, ensuring each part meets the highest quality standards.

7. Finishing & Delivery:Components are refined with post-processing finishes as required, then carefully packed and shipped, reaching customers promptly and in perfect condition.

Features that Make Our 5 Axis CNC Machining Unique

Our Certificates

5 Axis CNC Machining FAQs

5 Axis CNC Machining allows simultaneous movement across five axes—three linear (X, Y, Z) and two rotational (A, B). Unlike 3 or 4 Axis machining, which may require multiple setups, 5 Axis machining can create complex geometries in one go, ensuring higher precision, reduced setup time, and improved efficiency.

Industries like aerospace, automotive, medical, and electronics benefit greatly from 5 Axis CNC Machining. It’s ideal for applications requiring complex parts, high precision, and intricate designs, such as turbine blades, medical implants, and high-performance engine components.

5 Axis CNC Machining is versatile with materials, including metals (aluminum, titanium, stainless steel), alloys, plastics, and composites. This adaptability allows us to meet the specific needs of diverse industries, from lightweight aerospace parts to durable industrial components.

5 Axis CNC Machining is known for its high accuracy, capable of achieving tolerances as tight as ±0.001 inches. This level of precision makes it perfect for applications where exact specifications and fine detail are essential.

By enabling complex parts to be machined in a single setup, 5 Axis CNC machining minimizes the need for multiple setups, reducing labor and setup costs. It also shortens production time and improves overall efficiency, resulting in faster lead times and cost savings.

Our 5 Axis CNC Machining process includes rigorous quality inspections, from initial design validation to final dimensional checks using advanced metrology tools. Each part undergoes detailed inspections to ensure it meets exact specifications and industry standards before delivery.

Blogs About 5 Axis CNC Machining

Cast Aluminum vs. Machined Aluminum: Choosing the Right Material for Your Project

In the world of manufacturing, selecting the right aluminum product is crucial for optimizing performance, cost, and durability. This article explores the key differences between cast aluminum and machined aluminum, helping industries from aerospace to consumer products make informed decisions. Understanding these materials’ properties and applications can ensure that your next project achieves the highest quality standards.

Ensuring Precision in CNC Milling for High-Quality Machined Parts

In today’s competitive manufacturing world, achieving the highest level of precision in CNC milling is essential for creating reliable and efficient machined parts. This guide explores how to ensure precision in your project by leveraging advanced CNC milling machines and strategies. For industries such as aerospace, automotive, and medical devices, mastering precision is a crucial factor for success.

Mastering the Countersink: Drilling Perfect Holes in Metal Workpieces

Achieving a flawless countersink is essential for ensuring screw heads sit flush with or below the surface of a metal workpiece. This guide will explore the intricacies of creating a countersink hole and provide you with the insights needed to master this technique. Whether you’re in aerospace, construction, or crafting precision metal parts, understanding how to countersink a screw properly is crucial for seamless assembly and optimal durability.