Precision CNC Bending Services

Transform your metal fabrication projects with our expert CNC bending services. We ensure precise bends, exceptional quality, and customized solutions tailored to your needs. Get in touch for reliable and efficient service!

Your Reliable Metal Bending Manufacturer

Welcome to our company, your trusted partner in precision metal bending solutions. With over 10 years of experience in the industry, we have established ourselves as a leader in providing high-quality CNC bending services tailored to meet the diverse needs of our clients.

At our company, we leverage cutting-edge technology and advanced machinery to deliver exceptional results with every project. Our professional team of skilled technicians and engineers is dedicated to ensuring the highest standards of quality and precision in every bend, allowing us to cater to various sectors, including automotive, aerospace, and industrial applications.

We take pride in our commitment to excellence, focusing on innovation and customer satisfaction. Whether you require intricate designs or large-scale production runs, we have the expertise and capabilities to bring your vision to life. Choose our company for your metal bending needs, and experience the difference that quality, technology, and professionalism can make!

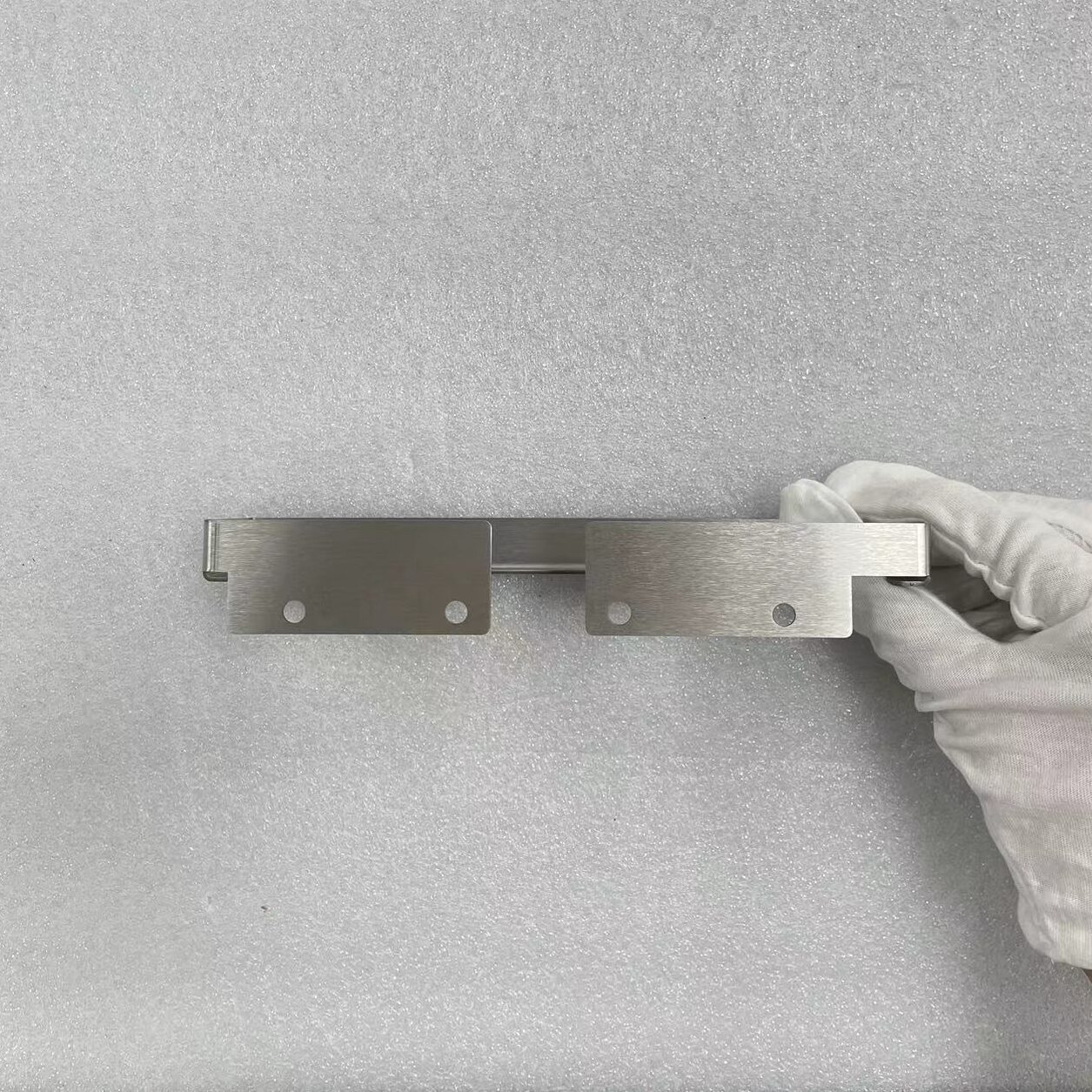

Metal Bending Customer Cases

Explore our Metal Bending Customer Cases to see how our CNC bending services have successfully transformed projects across various industries. Discover real-world examples of high-quality metal bending solutions that demonstrate our expertise, advanced technology, and commitment to customer satisfaction. From custom designs to large-scale productions, our case studies showcase the precision and reliability you can expect from our company. Contact us today to learn how we can elevate your next project!

Manufacturing Process of Metal Bending

1. Material Selection:We begin by selecting the appropriate metal material based on your project’s specifications. Common materials include aluminum, steel, and stainless steel, each chosen for their unique properties and suitability for bending.

2. Design & Prototyping:Our expert team collaborates with you to develop precise designs and prototypes. Using advanced CAD software, we ensure that every detail is accounted for, allowing us to visualize the final product and make any necessary adjustments before production.

3. CNC Programming:Once the design is finalized, we program our state-of-the-art CNC bending machines. This automated process allows for high accuracy and consistency, enabling us to replicate complex bends with ease and precision.

4. Bending Process:Utilizing hydraulic or mechanical bending methods, our CNC machines perform the bending operation. The metal is carefully shaped according to the programmed specifications, ensuring uniformity and quality throughout each piece.

5. Quality Control:Throughout the manufacturing process, we implement rigorous quality control measures. Each bent component is inspected for dimensional accuracy, surface finish, and overall quality to ensure it meets our high standards and your expectations.

6. Finishing Touches:After bending, we apply any necessary finishing processes, such as deburring, polishing, or coating, to enhance the durability and aesthetics of the final product.

7. Final Inspection & Delivery:Before shipping, each product undergoes a final inspection to verify compliance with your specifications. We prioritize timely delivery, ensuring your components reach you when you need them.

By following this meticulous manufacturing process, we guarantee high-quality metal bending solutions that meet the needs of our B2B clients across various industries.

Features that Make Our Metal Bending Unique

Our Certificates

Metal Bending FAQs

We can bend a variety of materials, including aluminum, stainless steel, mild steel, and brass. Each material has unique properties, and our team can help you choose the right one for your project based on strength, flexibility, and intended application.

Our CNC bending services offer tight tolerances, generally within ±0.01 mm. However, the specific tolerances may vary depending on the material and complexity of the design. We always strive to meet your exact specifications.

Absolutely! We specialize in custom metal bending solutions. Our team works closely with you to develop prototypes based on your designs, allowing for adjustments before full-scale production.

Lead times can vary depending on the complexity of the project and current workload. Generally, we provide estimates ranging from a few days to several weeks. We prioritize timely delivery and will keep you informed throughout the process.

We implement rigorous quality control measures throughout the manufacturing process, including inspections at multiple stages. Our experienced team checks for dimensional accuracy and surface finish, ensuring every product meets our high standards.

Yes, we provide various post-bending services, such as deburring, polishing, and coating. These finishing touches enhance the durability and appearance of your components, ensuring they are ready for your specific applications.

Blogs About Metal Bending

Cast Aluminum vs. Machined Aluminum: Choosing the Right Material for Your Project

In the world of manufacturing, selecting the right aluminum product is crucial for optimizing performance, cost, and durability. This article explores the key differences between cast aluminum and machined aluminum, helping industries from aerospace to consumer products make informed decisions. Understanding these materials’ properties and applications can ensure that your next project achieves the highest quality standards.

Ensuring Precision in CNC Milling for High-Quality Machined Parts

In today’s competitive manufacturing world, achieving the highest level of precision in CNC milling is essential for creating reliable and efficient machined parts. This guide explores how to ensure precision in your project by leveraging advanced CNC milling machines and strategies. For industries such as aerospace, automotive, and medical devices, mastering precision is a crucial factor for success.

Mastering the Countersink: Drilling Perfect Holes in Metal Workpieces

Achieving a flawless countersink is essential for ensuring screw heads sit flush with or below the surface of a metal workpiece. This guide will explore the intricacies of creating a countersink hole and provide you with the insights needed to master this technique. Whether you’re in aerospace, construction, or crafting precision metal parts, understanding how to countersink a screw properly is crucial for seamless assembly and optimal durability.