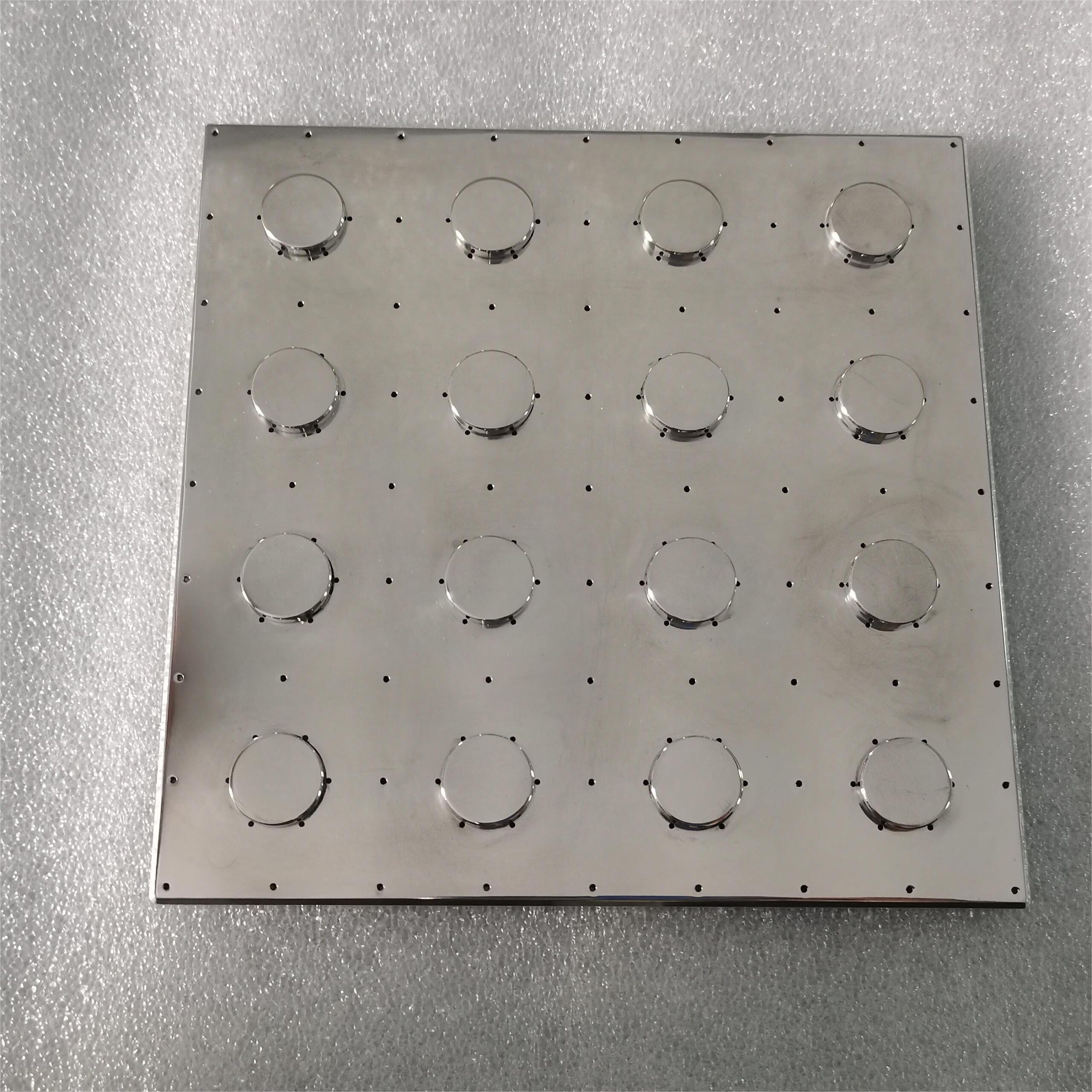

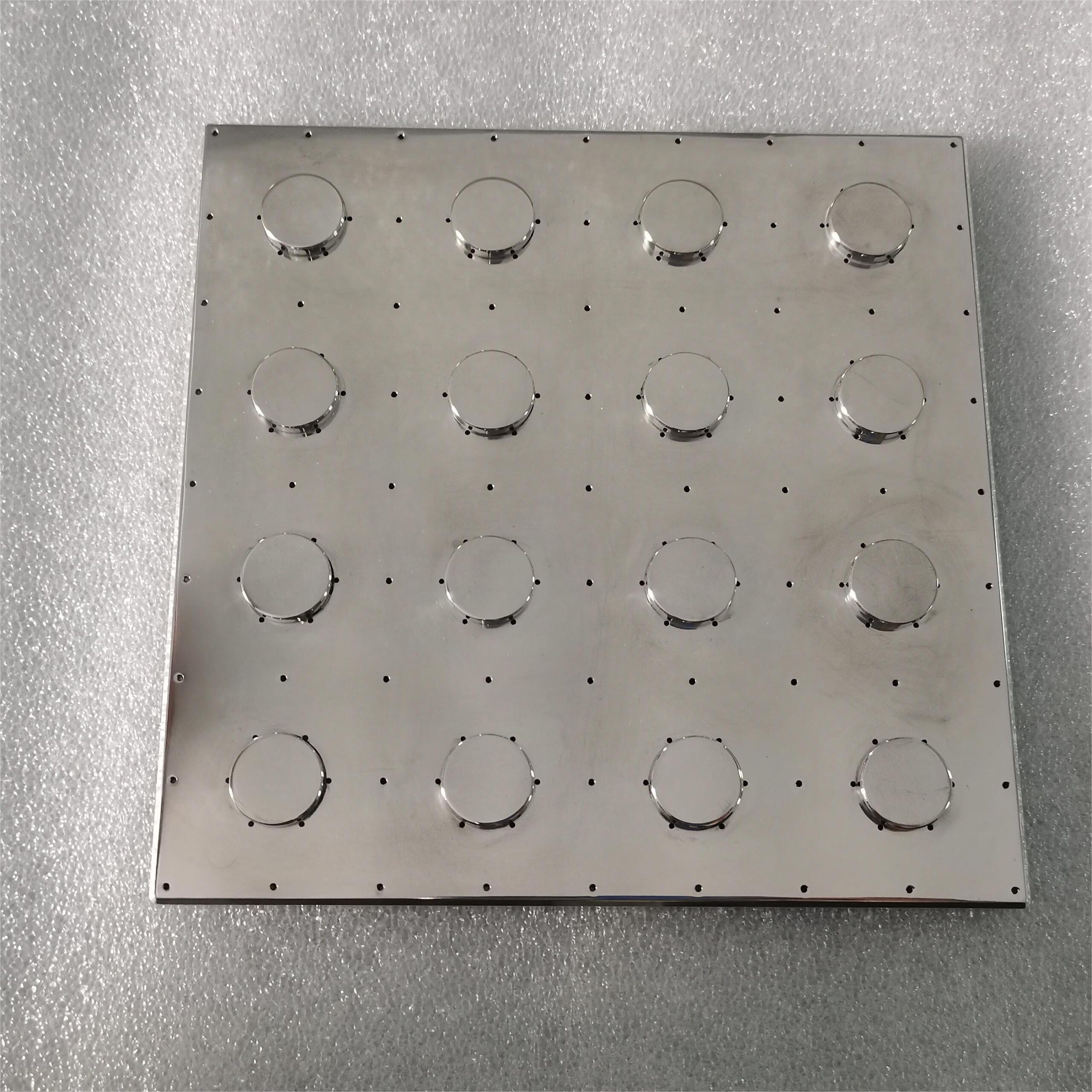

CNC Milling Aluminium 6082 with Mirror Polishing & Engraving

Precision CNC milling of Aluminium 6082 with mirror polishing, engraving, and standard inspection. Tolerance: +/- 0.127mm, surface roughness: 3.2μm Ra.

Service: CNC Machining

Material: Aluminum 6082

Surface Finish: As Machined

Secondary Finish: Silver Anodized

Tightest Tolerance: ±0.01mm

Minimum Surface Roughness: 3.2µm Ra

| Specification | Details |

|---|---|

| Tolerances | To be specified below unless otherwise indicated |

| Holes | |

| Dimensions | 2 DP ± 0.1 mm |

| 1 DP ± 0.25 mm | |

| None ± 0.4 mm | |

| Angular | ± 1° 12’ |

| Additional Tolerances | |

| D0 to D8 | +0.1 mm |

| D8 to D14 | -0.0 mm, +0.12 mm |

| D14 to D25 | -0.0 mm |

| Units | All dimensions are in millimeters unless otherwise stated. Apply tolerances after plating. |

| Standards | This drawing conforms to BS 8888. |

| Finish | Silver Anodized (BS 1615) |

| Material | 6082 Aluminum |

| Surface Texture Values | In µm Ra and conform to BS 1134. |

| Notes | Please ensure all burrs and sharp edges are removed. |

| Denotes part number. |

| Category | Details |

|---|---|

| Machining Equipment | CNC Machining Centers, CNC Lathes, Grinding Machines, Milling Machines, Lathes, Wire EDM Machines, Laser Cutting Machines, CNC Shearing Machines, CNC Bending Machines, etc. |

| Processing Capabilities | Turning, Milling, Drilling, Wire EDM, Welding, Casting, Forging, Assembly, etc. |

| Tolerance | ±0.005mm |

| Materials | Aluminum, Copper, Stainless Steel, Ball Bearing Steel, Abrasive Tool Steel, Engineering Plastics, Nylon, and more. (Contact us for other materials.) |

| Surface Treatments | Black Oxide, Polishing, Anodizing, Chrome Plating, Zinc Plating, Nickel Plating, Ion Nitriding, Titanium Nitriding, and more. |

| Product Design | Customized as per customer’s drawings or samples. |

| Inspection Tools | Tool Microscopes, Digimatic Micrometers, Inside Micrometers, Dial Gauges, Electronic Digital Calipers, Automatic Height Gauges, Precision Level Detectors, Marble Platforms, Ring Gauges, etc. |

| Quality Control System | 100% inspection according to: MIL-STD-105E, ANSI ASQC Z1.4, ABC-STD-105, BS6001, ISO 2859, DIN 40080 before shipment. |

| Minimum Order Quantity | 1-10 pcs (Just for samples) |

We can work with a wide range of materials, including metals like aluminum, steel, brass, and titanium, as well as plastics such as acrylic, nylon, and polycarbonate. The choice of material often depends on the specific requirements of your project, including strength, weight, corrosion resistance, and budget.

Answer: The lead time for custom CNC parts can vary based on the complexity of the design, the material used, and the quantity ordered. Generally, standard orders can take anywhere from a few days to several weeks. We prioritize communication and will provide you with a clear timeline based on your specific needs.

Answer: Quality assurance is a crucial part of our process. We implement rigorous inspection protocols, including precision measurements, material testing, and visual inspections throughout the production process. We also use advanced CNC machinery that adheres to industry standards, ensuring that every part meets your specifications.

Answer: Yes, we specialize in both small and large batch orders. Whether you need a single prototype or a small production run, we can customize our services to meet your requirements. This flexibility allows you to test designs or meet specific project needs without committing to large quantities.

Answer: The ordering process is straightforward:

Consultation: Reach out to discuss your project requirements.

Design Submission: Provide your CAD files or design specifications.

Quotation: We’ll give you a detailed quote based on your specifications.

Production: Once approved, we begin manufacturing your parts.

Delivery: After quality checks, your custom parts will be shipped to you.

Answer: We offer design assistance services to help you optimize your part for manufacturability. Our experienced engineers can provide insights on material selection, design modifications, and production techniques to ensure your part functions as intended while being cost-effective.

Precision CNC milling of Aluminium 6082 with mirror polishing, engraving, and standard inspection. Tolerance: +/- 0.127mm, surface roughness: 3.2μm Ra.

High-quality aluminum alloy extrusion profiles, customized sizes, and finishes for the auto industry. ISO9001 certified with quick delivery and diverse processing services.

High-quality die casting with aluminum, zinc, and brass materials. OEM service with fast delivery and tooling. Suitable for automotive & artware applications.

Shenzhen Runkey Precision Technology Co. Ltd, a subsidiary of the Tensun Group, is your trusted one-stop solution for custom manufacturing from prototyping to production.Transforming your idea into reality with digital manufacturing resources,streamlined processes, expert guidance,accelerated timelines, and uncompromising quality.

©2024. CNC Fabrication All Rights Reserved.