Precision Fabrication Services Delivered

Offering top-tier fabrication services tailored to your business needs. Get precise, high-quality results with our expert solutions.

What are fabrication services used for ?

Fabrication services are used to create parts, structures, and components from raw materials, typically metals, plastics, or composites. These services involve processes like cutting, bending, welding, machining, and assembling to produce both small components and large structures. Fabrication is commonly employed in industries such as:

Manufacturing: Custom parts, machinery components, and prototypes.

Construction: Structural steel, metal frameworks, and infrastructure elements.

Automotive: Custom vehicle parts, frames, and equipment.

Aerospace: Precision components for aircraft and spacecraft.

Energy: Equipment for power plants, oil rigs, and renewable energy systems.

Electronics: Custom enclosures, brackets, and chassis for devices.

Fabrication services ensure high precision and customization for industries requiring tailored components or structures.

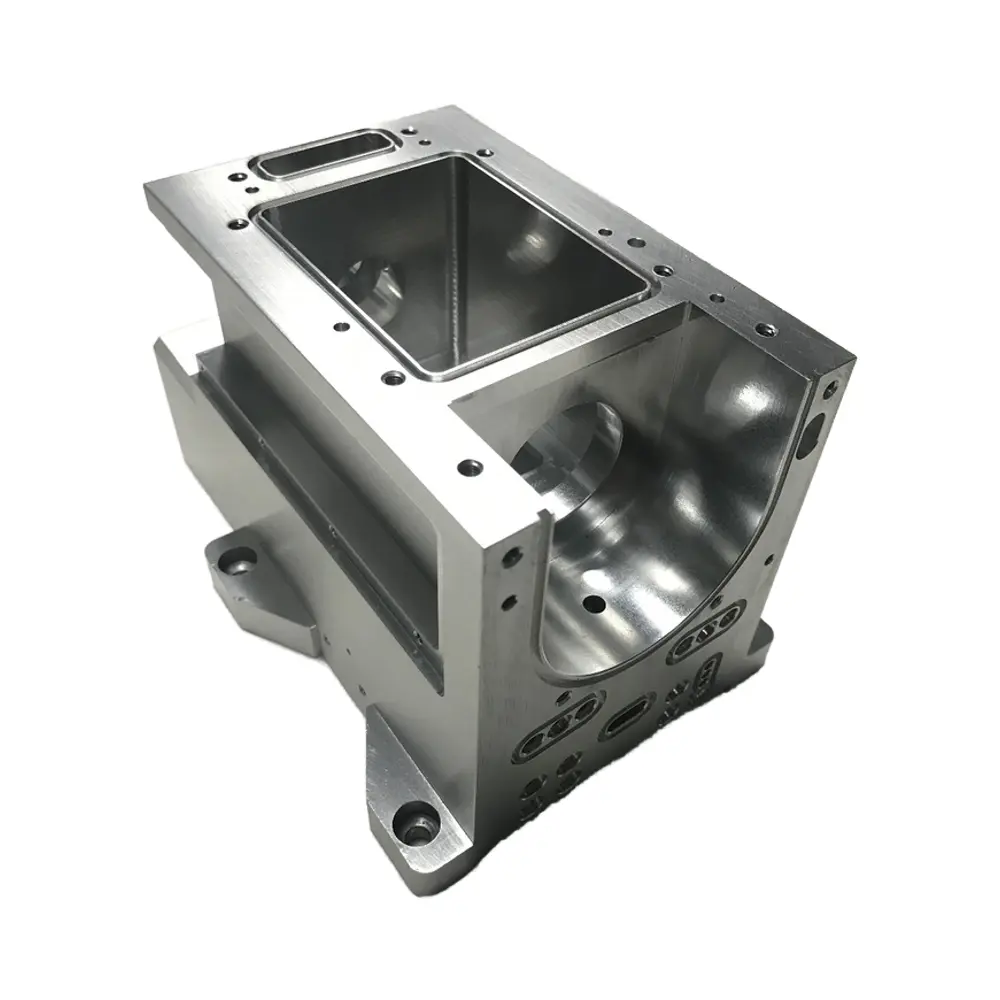

Fabrication Services Classification

Fabrication services cover processes like cutting, welding, and machining to create custom components from metals, plastics, or composites. Serving industries from automotive to aerospace, these services offer precise, tailored solutions for manufacturing, construction, and more.

Sheet Metal Fabrication

Our CNC sheet metal fabrication service delivers high-precision, custom metal parts for a wide range of industries. With advanced technology and skilled craftsmanship, we provide fast turnaround, cost-effective solutions for prototypes and large production runs. Quality guaranteed.

Laser Cutting

Our CNC laser cutting services offer precise, high-quality metal cutting solutions for various industries. Using advanced laser technology, we deliver fast, cost-effective custom cuts for prototypes and large-scale production. Achieve superior results with guaranteed precision and reliability.

Die Casting

Our China CNC punching and low-pressure die casting services deliver high-precision, custom metal parts for various industries. Specializing in durable, cost-effective solutions, we ensure fast production for prototypes and large runs. Quality craftsmanship and reliable results guaranteed.

Metal Bending

Our CNC bending services provide accurate and high-quality metal bending solutions for diverse industries. Using advanced CNC technology, we deliver custom bends for both small and large production runs. Fast turnaround, cost-effective, and precision guaranteed to meet your exact specifications.

Aluminum Extrusion

As leading aluminum extrusion CNC suppliers, we offer high-precision, custom aluminum extrusion solutions for various industries. Our advanced CNC technology ensures efficient production, from prototypes to large-scale runs. Trust us for cost-effective, reliable, and top-quality results.

Wire EDM

As a trusted CNC wire EDM machine supplier, we provide high-precision wire electrical discharge machining solutions for intricate part manufacturing. Our advanced technology ensures excellent accuracy and finish, making it ideal for various industries. Count on us for reliable, efficient, and cost-effective wire EDM services.

Manufacturing Process of Fabrication Services

1.Consultation and Design:Collaborate with clients to understand project requirements and specifications.

Utilize CAD software to create detailed designs and prototypes for client approval.

2.Material Selection:Identify and source high-quality materials suitable for the fabrication project.

Consider factors such as strength, durability, and cost-effectiveness.

3.Cutting:Employ precision cutting techniques, such as laser cutting, plasma cutting, or waterjet cutting, to shape materials according to specifications.

Ensure clean and accurate cuts to minimize waste and prepare for the next fabrication steps.

4.Bending and Forming:Use CNC bending machines to accurately bend and form materials into desired shapes.Apply various techniques (e.g., press brake bending) to achieve complex geometries.

5.Welding and Assembly:Utilize advanced welding techniques (MIG, TIG, etc.) to join components securely.

Conduct thorough inspections during assembly to ensure structural integrity and adherence to specifications.

6.Finishing Processes:Apply finishing treatments such as sanding, grinding, or polishing to achieve the desired surface finish.

Offer additional services like powder coating or painting for enhanced aesthetics and corrosion resistance.

7.Quality Control:Implement rigorous quality control measures throughout the fabrication process.

Conduct inspections and testing to ensure all products meet industry standards and client specifications.

8.Packaging and Delivery:Carefully package finished products to prevent damage during transit.

Coordinate logistics for timely delivery to clients, ensuring all orders are fulfilled efficiently.

9.Post-Delivery Support:Provide ongoing support to clients for any inquiries or adjustments needed post-delivery.

Gather feedback to continuously improve fabrication processes and customer satisfaction.

Features that Make Our Fabrication Services Unique

Our Certificates

Fabrication Services FAQs

We work with a wide range of materials, including steel, aluminum, stainless steel, and plastics. Our team can recommend the best material based on your project requirements, including strength, weight, and cost considerations.

Yes, we specialize in custom fabrication services. Our team collaborates with clients to create tailored solutions that meet specific needs, ensuring that all designs align with your exact specifications and requirements.

Lead times vary based on project complexity and size. Generally, we aim for quick turnaround times without compromising quality. Once we understand your project scope, we can provide a more accurate timeline.

Absolutely! We implement strict quality control measures throughout the fabrication process. Our team conducts thorough inspections and tests to ensure all products meet industry standards and client expectations.

We serve a diverse range of industries, including automotive, aerospace, construction, and manufacturing. Our expertise allows us to adapt our fabrication services to meet the unique needs of various sectors.

Yes, we offer prototyping services to help you visualize and test your designs before moving to full-scale production. This allows for adjustments and improvements, ensuring the final product meets your expectations.

Blogs About Fabrication Services

Cast Aluminum vs. Machined Aluminum: Choosing the Right Material for Your Project

In the world of manufacturing, selecting the right aluminum product is crucial for optimizing performance, cost, and durability. This article explores the key differences between cast aluminum and machined aluminum, helping industries from aerospace to consumer products make informed decisions. Understanding these materials’ properties and applications can ensure that your next project achieves the highest quality standards.

Ensuring Precision in CNC Milling for High-Quality Machined Parts

In today’s competitive manufacturing world, achieving the highest level of precision in CNC milling is essential for creating reliable and efficient machined parts. This guide explores how to ensure precision in your project by leveraging advanced CNC milling machines and strategies. For industries such as aerospace, automotive, and medical devices, mastering precision is a crucial factor for success.

Mastering the Countersink: Drilling Perfect Holes in Metal Workpieces

Achieving a flawless countersink is essential for ensuring screw heads sit flush with or below the surface of a metal workpiece. This guide will explore the intricacies of creating a countersink hole and provide you with the insights needed to master this technique. Whether you’re in aerospace, construction, or crafting precision metal parts, understanding how to countersink a screw properly is crucial for seamless assembly and optimal durability.